Virtual

net in a real environment

Acad. Ms. Arq. Silvia

Lenyra Meirelles Campos Titotto

Department of

Design and Architecture, Faculty of Architecture and Town Planning,

University of

São Paulo

e-mail: titotto@gmail.com

Acad. Eng.

Felipe Estrella Barros

Department of

Energy and Automation, Polytechnic School,

University of

São Paulo

e-mail: festrella@uol.com.br

Profa. Dra.

Clice de Toledo Sanjar Mazzilli

Department of

Design and Architecture, Faculty of Architecture and Town Planning,

University of

São Paulo

e-mail: clicemazzilli@terra.com.br

Abstract

This project consists on an

installation of several common laser beans (models of

laser beans that are normally used

on presentations), mirrors and a light sensor (LDR - Light Diode Resistor).

The laser beans are positioned with

their aims focused on the mirrors. Through the

reflection of the mirrors, it is

possible to create virtual obstacles. If a person or an

object crosses the laser, the light

sensor notices the interruption and will trigger an

alarm. A source power will be

developed in order to replace the laser beans'

batteries and the alarm circuit. The

alarm circuit will be also designed for this work.

Working Principle

The conception

of this project is directed to the study of the environment response due to a

human action. Based on that subject, an environment was prepared with several

visible rays of laser. If one of theses rays is interrupt (eg. someone crosses

it), an alarm will be triggered. Therefore, the space of the environment is

sensible to the presence of people.

It can be also

quite interesting to try to dodge the rays, as if it was a virtual barrier or

labyrinth existing in a real space.

Technical Issues

Power

Source

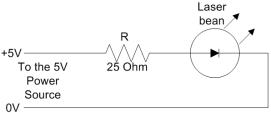

The reason to develop the power source is to replace

the laser beans batteries - which don’t have autonomy greater than a couple

hours - and also to feed the trigger circuit (see circuit diagram on figure 1).

The AC input chosen was 220 V, because it is the

voltage provided in Europe.

There are two different outputs. One output is

stabilized, with DC 5 V and 5 W maximum power. It has the purpose to feed the

laser beans. The 7805 voltage regulator is the one that best suits to the

lasers connections, because it’s voltage output is 5 VDC, while the beans need

4.5 V. The difference of the voltage will be solved through the insertion of a

resistor in series with each bean.

The other output will be used on the alarm circuit. It

is not stabilized and has 12 VDC voltage with 40 W maximum power output.

|

|

|

Figure 1 – Stabilized 5 V power source |

Laser

Beans

This experiment will have 4 laser beans, fed by the 5

V power source. Each laser bean works with a 4.5 V voltage and 20 mA current. Therefore, using the Ohm’s law,

follows:

|

|

(1) |

The resistor R calculated in (1) will be set in series

with each laser bean, as represented on figure 2.

|

|

|

Figure 2 – Connection of the beans to the Power

Source |

Alarm

Circuit

The alarm circuit consists on a LDR sensor (Light

Diode Resistor) that operates as a trigger of the BC327 transistor. If the ray

of laser stops falling upon the LDR (eg. a person or an object has crossed the

laser ray), it will make the transistor enter on its conducting procedure. If

the transistor starts conducting, it will energize the relay. The relay has an

electric seal that keeps it energized even if the transistor stops conducting.

The siren is connected through the relay to the 12V power source, therefore, if

the relay is activated, the alarm is triggered.

The only way to reset the alarm is to push the

pushbutton break.

The alarm circuit’s sensibility is adjusted by the

potenciometer.

The circuit diagram is shown on figure 3.

|

|

|

Figure 3 – Alarm circuit diagram |

Mirrors

and support

The project will have 13 mirrors, with dimensions of

50x50 mm and transparency equal or greater than 70%. They will be attached on

55x55x20 mm cubical pieces of wood.

A hole of 6mm2 will transpose the lateral

of the wood, in parallel with its surface. Through this hole, it will be stick

a piece of cable, very hard and with thickness of 6 mm2. Glue can be

used in order to fixate the wire inside the hole.

The support can also be made of wood. A rectangular

base of heavy wood (about 5 kilos) should be enough. A vertical wood stick made

of brown stick can be settled trough a hole on the base.

The mirrors will be placed on the vertical stick

through 6 mm2 horizontal perpendicular holes, which will receive the

wire from de mirrors.

The mirrors adjusts will be made by deforming and

twisting their wire. The laser beans and the LDR sensor can also be attached

through this 6 mm2 wire to the bases.

Another possibility to fixate the lasers and the

mirrors is to attach the devices on common professional microphones stabling

systems (see figure 6 ).

Room

environment

It is imperative to prepare the room for almost

complete darkness, otherwise the lasers won’t be seen. To provide a carrier in

the air that helps to make the rays of laser more visible, a glycerin smoke

machine can be used.

The Results

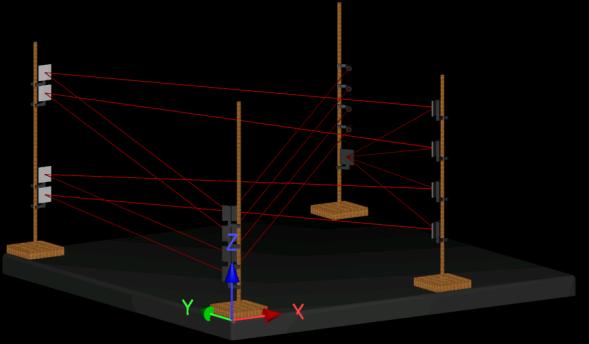

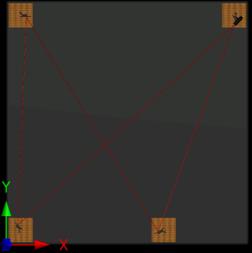

This installation was simulated in a CAD system, and

some angles of it were rendered in order to demonstrate the environment. On

figure 4, there is an isometric view of the installation, made on a square

space.

|

|

|

Figure 4 – Isometric view of the installation |

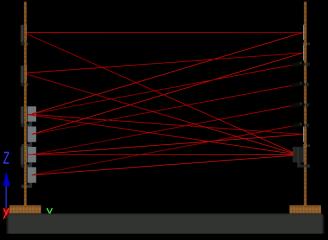

Figure 5 shows the top and side views of the

installation.

|

|

|

|

Figure 5 – Top view (on the left); side view (on the

right) |

|

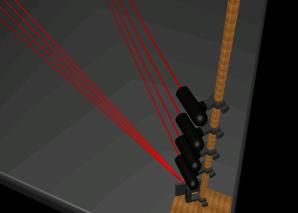

The mirrors and lasers were sketched with an attaching

system based on microphone stabling devices.

|

|

|

|

Figure 6 – Four mirrors set on a wood base (on the

left); Four laser beans and a mirrors set on a wood base (on the right) |

|